1. Oil drilling grade CMC used in fracturing fluid, drilling fluid and well cementing fluid as fluid loss controller and tackifier.

It can protect the shaft wall and prevent mud loss thus enhance recovery efficiency.

2. Detergent grade CMC, when used in liquid, paste detergent, acts as stabilizing agent and thickening agent; When used in detergent powder, CMC can effectively prevent washes from becoming contaminated after being washed by synthetic detergent.

3. CMC used in textile and dyeing industry as sizing agent and dying adjuvant to make stock limpidity and transparence.

It is easy a good stabilizer of the stock and helps to form film. It is easy to desizing.

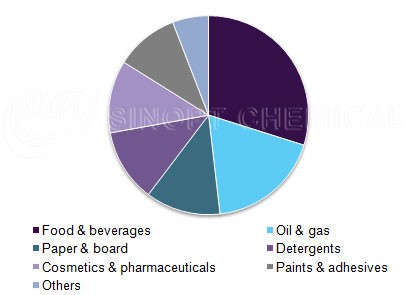

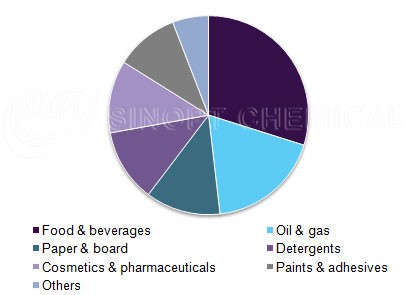

Global CMC market volume by application

4.CMC in Food Industry:

CMC is widely used in frozen desserts, protein food, beverages, icings, dressings, instant noodles, etc.

5.CMC in Ceramic Industry

1)CMC for ceramics features uniform distribution of substituents (carboxy methyl group) on the cellulose backbone. It produces fewer gel granules in glaze formulation.

2)It contains no colored impurity and is 100% combustible under firing condition,

to ensure clean ceramic glaze.

3) It can stabilize physical and chemical property of glaze formulation.

4) It can improve glaze adhesion and reduce glaze cracking.

5) It facilitates formation of a smooth dense glaze layer.

6) It can improve the rheological property of glaze formulation.

7) The glaze viscosity is proportional to the concentration of CMC added.

.jpg)

.jpg)

.jpg)

.jpg)

(1).png)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

(1).jpg)

.jpg)

.jpg)

.jpg)

(2).jpg)